Schaeffler at Agritechnica 2025 (Hall 15, Booth E13) Higher efficiency, lower emissions – modern agricultural technology solutions

2025-10-22 | Schweinfurt

- Significant efficiency gains through electrification and sensorization of traction drives and work functions

- Friction-reduced rolling bearings to help agricultural technology manufacturers significantly lower the energy consumption of their agricultural machinery

- EWELLIX electromechanical linear actuators as alternatives to hydraulic cylinders

The agriculture and farming equipment industry continually faces the challenge of ensuring both sustainability and long-term viability. One key approach to achieving this balance is by improving machinery efficiency. At Agritechnica, the world’s leading trade fair for agricultural machinery, Schaeffler – The Motion Technology Company – will showcase a comprehensive portfolio of solutions designed to help customers develop reliable equipment that operates safely and efficiently, even in the most demanding environments.

In addition to highly efficient electric traction motors and new electromechanical linear actuators, friction-reduced rolling bearings will be the focus of the trade show appearance. Additionally, Schaeffler will present sensor solutions that can record torques, loads, and other data and help to increase precision, productivity, and profitability in agricultural production.

“We are known for our high-performance bearings, which can also be used in extremely challenging conditions. With the expanded offering – for example, in sensor technology or with our electric motors – we are also able to support our customers in the development of highly efficient machines and the further development of autonomous agriculture and farming equipment,” says Patrick Scherr, Global Sector Lead Offroad at Schaeffler.

Through solutions for the electrification of traction drives and work functions or by means of an electric PTO, Schaeffler is designing future-ready solutions that are fundamental to achieving more efficient and thus more sustainable agricultural technology.

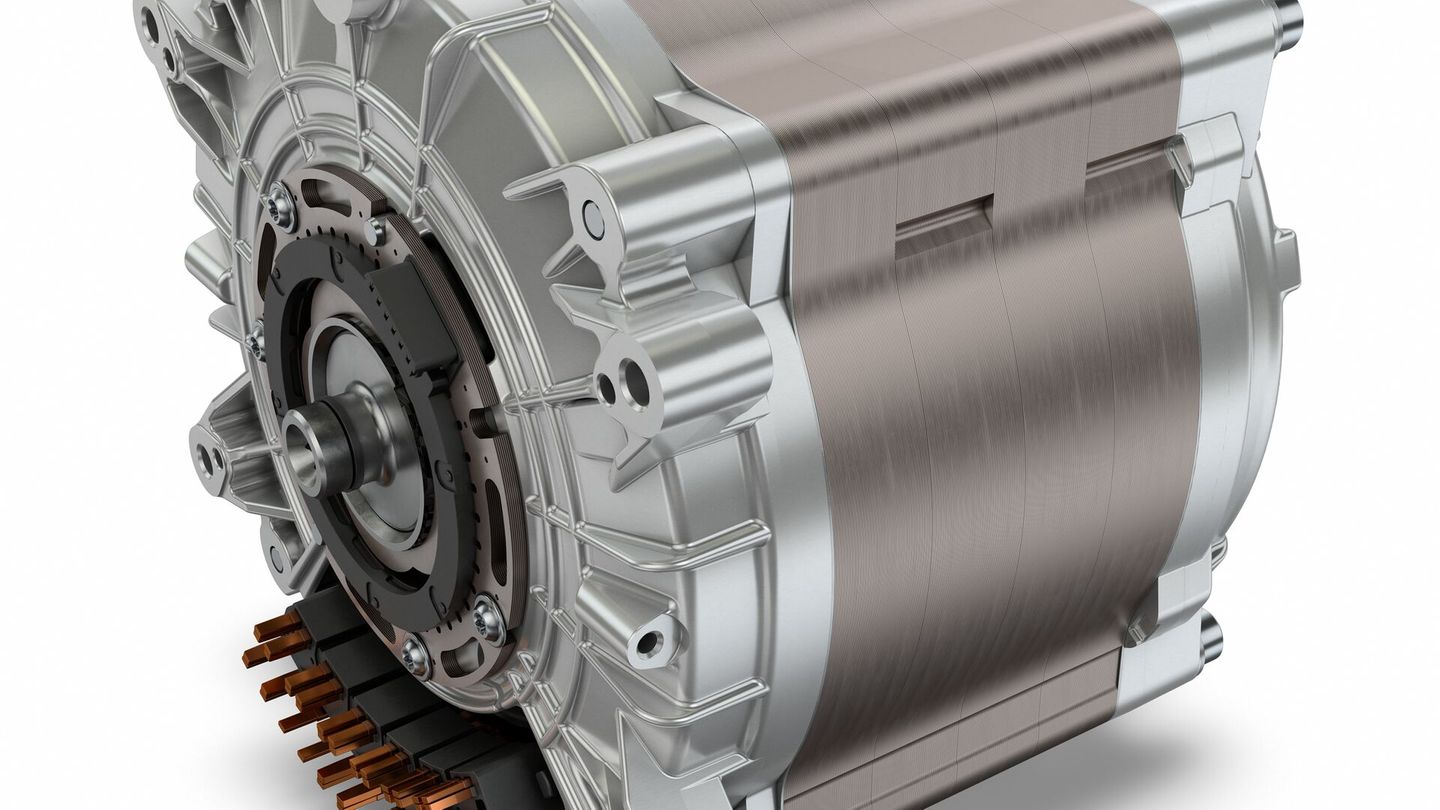

Great potential for electric motors as main drives

For the first time ever, Schaeffler will present to the agricultural industry its highly efficient heavy-duty electric motors as a complete motor family with continuous outputs of 110 to 220 kW and peak outputs of 140 to 310 kW. The independent power electronics feature a four-quadrant drive controller, allowing braking energy to be recovered from the traction motor in overrun mode.

Electric motors can also be used as highly efficient generators in combination with diesel engines and then provide the electrical energy for the traction drives. Due to the compact external dimensions, electric motors can also be used as electric PTOs (ePTOs). Independent of the powertrain and able to be positioned anywhere, they offer an especially high degree of design freedom.

Electrification of work function with linear actuators

The new electromechanical EWELLIX linear actuators in the EMA-80 series are also pointing the way to the future. When these “oil-free cylinders” are used for various work functions, the focus is on optimized crop yield, lower energy consumption (power on demand), energy recovery (recuperation), and lower operating costs. Used in conjunction with Schaeffler’s sensor solution for measuring loads, on front loaders, for example, they can precisely record bulk material amounts. This solution is suitable for both original equipment and retrofitting.

Improving performance and efficiency with rolling bearings

Rolling bearings are inherently low-friction. At Agritechnica 2025, Schaeffler will demonstrate that it is still possible to reduce friction and simultaneously improve performance with its new X-life tapered roller and cylindrical roller bearings. In these bearings, the coefficient of friction at the rib contacts was significantly reduced, the surfaces on raceways and rolling elements were improved, and the cage geometry and the dimensions of the rolling elements and raceways were adapted. Compared with conventional tapered roller bearings, these X-life bearings have 25 percent higher dynamic load ratings, 10 percent higher nominal speeds, and 75 percent less friction. But it gets better: for extremely stressed bearing positions, the tapered roller bearings are subjected to a special heat treatment, which leads to 33 percent higher dynamic load ratings and makes the bearings less sensitive to contamination.

Robust and durable bearing units for tillage disks

Schaeffler presents the “Schaeffler Field Pro,” a bearing system that has been optimized for tillage disks – with the patented Corrotect corrosion protection system, a triple seal system, and an exceptionally robust construction. Both the ball bearings and the cassette seals are friction-reduced. The grease between the two sealing lips serves as a barrier grease and at the same time reduces friction. An optimized contact angle for the angular contact ball bearings ensures more precise guidance of the disks. With these design improvements, the bearing units are particularly smooth-running, very stiff, and lubricated for the entire service life.

Smart farming: high-tech torque sensor system for higher efficiency

Materials to be spread and crops to be harvested have fluctuating consistencies. To prevent this heterogeneity from negatively affecting the spreading pattern, fertilizer consumption, crop quality, and yield, all processes must be monitored almost in real time and adjusted as needed. In spreaders, balers, and forage wagons and on PTOs, the torque is often the process-controlling variable, and the exact measurement of the torque is a basic prerequisite for precise control. Schaeffler offers torque measuring modules for this purpose. They can be used as standalone sensor modules or integrated into powertrains.

Publisher: Schaeffler Technologies AG & Co. KG

Country: Germany

Terms of use for Schaeffler press pictures

Schaeffler press pictures may only be used for editorial purposes. Unless otherwise stated, all copyrights and rights of use and exploitation are owned by Schaeffler Technologies AG & Co. KG, Herzogenaurach (Germany) or by one of its affiliated companies. The reproduction and publication of Schaeffler press pictures is only permitted if the source is stated as follows: "Image: Schaeffler". The pictures may be used free of charge in such cases. The use of pictures for advertising or other commercial purposes, in particular their disclosure to third parties for commercial purposes, is hereby prohibited. Pictures may only be edited with the approval of Schaeffler.

We kindly request that a specimen copy be sent to us when Schaeffler press pictures are published in printed media (or a digital copy in the case of publication in electronic media). When using Schaeffler press pictures in films, please notify us and state the title of the film.

Use and utilization of Schaeffler press pictures is subject to the substantive laws of Germany without its conflict of law provisions. The place of competent jurisdiction shall be Nuremberg, Germany.

Postal address:

Schaeffler Technologies AG & Co. KG

Corporate Communication

Industriestrasse 1-3

91074 Herzogenaurach

Germany

Press releases

Package (Press release + media)