Special linear motors

The single-phase Moving Coil linear motors are working according to the electrodynamic principle. They are designed for positioning or vibrating in the range of a few millimetres.

A movable coil system of minimized mass forms the base of a highly dynamical movement of rather lightweight masses. These systems allow moving and positioning especially in the case of light-weight masses in a highly dynamical fashion.

The single-phase Moving Magnet linear motors are working according to the electrodynamic principle. They are designed for positioning or vibrating in the range of a few millimetres.

The externally mounted coil system has a mechanical heat conducting connection to its environment. Consequently, the drive system has very relaxed requirements for heat leakage and cooling. Compared to other direct drives the moving magnets have important benefits for the user because of their fixed stationary coil system and their compact armature.

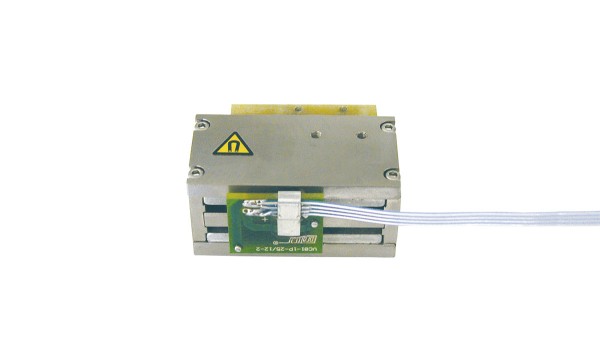

The short stroke linear module LRAM is based on a linear two-phase hybrid stepper motor. The special feature is that only the teeth of the passive motor part are moved. They are fixed in a thin ceramic plate. This plate is supported by an air bearing. A second plate is arranged perpendicular to the first, providing lateral guidance. This design ensures an extremely low moving mass (10 g) with wear free air bearing. There is no connection necessary to the moving part. The advantage of the low moving mass is high acceleration up to 1000 m/s² as well as a low impulse input into the base system.

A simple magneto resistive encoder is integrated based on an iron tooth scale in the second ceramic plate. Thus the axis can be run in a closed loop as a servo drive. No cooling is necessary at a high nominal force. Dimensions and force can be customized to special applications.

Applications:

- Applications with high dynamic requirements

- Precise positioning of parts with low mass

- Applications with high positioning cycles

- Handling and test systems

- Pick and place applications

- Turn lift module in combination with a rotary micromotor.