Linear motors L7

L7, the latest generation of linear motors sets the standard in efficiency and force density. Up to 50% lower power losses at the same force and up to 40% higher continuous force lower costs and improve productivity.

L7 linear motors are slotted, permanent magnet-excited AC synchronous motors with peak forces of up to 24,300 N. The motors have a highly efficient cooling system in the primary part.

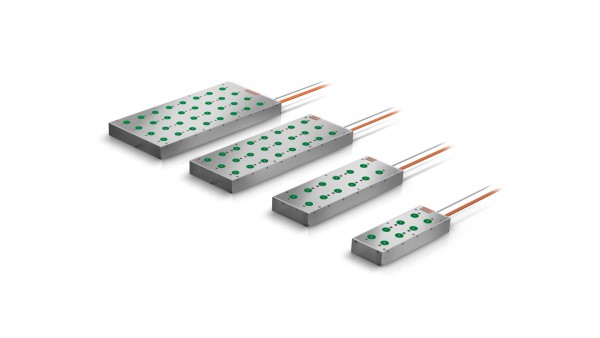

The L7 series of linear motors comprises twelve motor sizes. These can be divided into the four widths for the secondary part of 100, 150, 200, and 300 mm. The widths can be combined with one of the three primary part lengths of 350, 500, and 650 mm.

Features:

- High-pole permanently excited synchronous linear motor

- Available in 3 active length (coil system length) and 4 magnetic track widths

- Mechanically interchangeable with market standard

- Reinforced insulation for DC link voltages up to 800 V

- Highly efficient cooling system

- Optionally available with encapsulated secondary part

Benefits:

- Higher contour accuracy

- Higher productivity due to up to 40% more continuous force

- Reduced operating costs thanks to up to 50% less power loss

- Reduced CO2 emissions

- Higher dimensional accuracy of produced parts due to reduced heat input into the machine bed

- Longer service life and robustness due to optional encapsulation

Applications:

- Milling machines

- Turning machines

- Laser machining

- Surface grinding machines

- Out-of-round machining

- Oscillation machining

- HSC axes

- PCB drilling machines