Torque motors

The current generation of torque motors display outstanding, unprecedented performance characteristics. These are achieved through the optimum combination of the appropriate bearing and the required measuring system. Schaeffler recommends different motor types for specific applications, which are perfect with regard to torque, synchronisation and design.

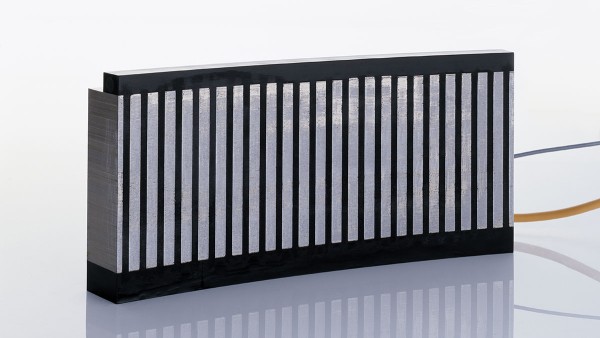

Rotary direct drives made by Schaeffler form the foundation for constructing the most powerful rotary axes in the world. Torque motors are ideal for mechanical engineering applications where high torque and optimum synchronisation are required.

Maximum power output is ensured by the highly efficient, closed cooling system.