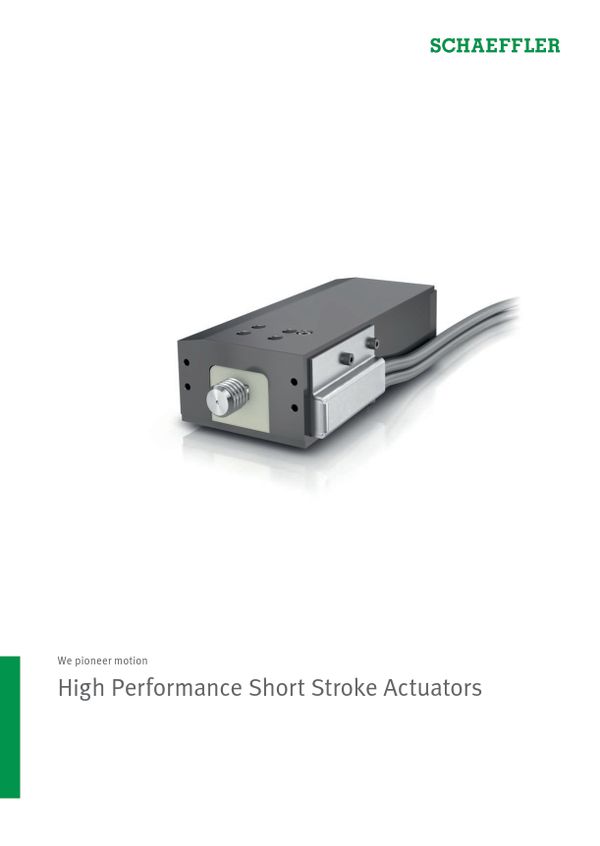

Z-axis systems

The right drive solution is significant for achieving perfect motion. This is particularly important in high precision, rapidly recurring operations in automation and handling. To do this, you should definitely call in an expert: Schaeffler Industrial Drives. Schaeffler Industrial Drives offers Z-axis systems (short stroke actuators) for fast pick and place applications, optical inspections, testing machines etc. to increase productivity. Of course, these are precisely matched to the productronics sector – including control and measuring system. We offer excellent service as well. Where else would you find everything from a single source?

Z-axis with voice coil: LDDS-078

Features:

- Short-stroke axis with compact design

- High force density

- Very low power loss

- Low moving mass

- Motor with small electrical time constant

- Integrated measurement system

Benefits:

- Small installation space necessary

- Low warming of the axis

- High axis dynamic, low impulse transfer to the machine

- Highest production output at highest reliability over one billion cycles

- Precise, regulated movement and positioning

- Maintenance free

Applications:

Test and sorting machines, Indexers, e.g. in the electronics industry, or medical engineering, in the productronics area

Further options on request.

Z-axis with slotted linear motors: LDDS-032

Features:

- High force density

- Attraction force compensated for extending linear guidance life time

- No moving cables

- Two slotted linear motors inside, type: L1B-3P-100x50

Benefits:

- Small installation space necessary

- Very long service life

- Low cabling effort

- Simple control

Applications:

Pick and place applications, in the productronics area, for fast cycles

Short stroke Z-axis with 2-phase hybrid stepper motor: LRAM

Features:

- Short stroke linear axis with air bearing in compact design

- 2-phase hybrid stepper motor with moving, air bearing ceramic plate

- Magneto-resistive measuring system

- No cooling required

Benefits:

- High acceleration up to bis 1000 m/s²

- Wear-free, precise air bearing

- Low moving mass (10 g)

- Low impulse input into the base system

- High nominal force

- Dimensions and forces can be customized to special applications.

Applications:

Applications with highly dynamic requirements, precise positioning of parts with low mass, applications with high positioning cycles, handling and testing systems, pick and place

Turn lift unit in combination with a micromotor is possible.